STEPS TO CONVERT TO A TOTAL SOLID-FEED SYSTEM

Determine the size of the system you need

Select Your Chemistry

Select Your Equipment

Installation & Monitoring

What Is Smart Release Technology

Smart Release Application

Smart Release® Technology uses concentrated chemistries which require fewer pounds of product per system than traditional liquids. Simply calculate the required pounds of each product and the corresponding feed equipment required based upon the cooling system’s annual gallons of blowdown.

Alternatively, use the table below to determine the estimated annual usage of each product based upon the system size.

Estimated Annual usage by product |

||||

|---|---|---|---|---|

| Gallons of Blowdown per Year | Scale & Corrosion Inhibitor | Oxidizing Biocide Usage | Non-Oxidizing Biocide Usage | |

| 125,000 gallons | 25lbs | 12lbs | 5lbs | |

| 250,000 gallons | 50lbs | 24lbs | 10lbs | |

| 500,000 gallons | 100lbs | 48lbs | 21lbs | |

| 1,000,000 gallons | 200lbs | 95lbs | 42lbs | |

| 1,500,000 gallons | 300lbs | 143lbs | 63lbs | |

| >1,500,000 gallons | Please consult with a Smart Release® representative for proper sizing. | |||

For more specific intermediate system sizes, use the following conversions to estimate annual chemical usage:

- 1lb Scale and Corrosion Inhibitors = 5,000 gallons of blowdown

- 1lb Oxidizing Biocide = 10,500 gallons of blowdown

- 1lb Non-Oxidizing Biocide = 25,000 gallons of blowdown

Size the system for peak monthly usage. Do this by dividing the total gallons of blowdown for this peak month by the amount of blowdown that is treated by 1lb of chemistry. Then, select the number of feeders needed to accommodate the required chemical usage.

Do you know what you’re looking for?

Continue to Step 2: Select Your Chemistry >

CHEMICAL PRODUCT SELECTION

We offer solid controlled release tablets to prevent scale and corrosion in your cooling application.

Products |

CW211-SR |

CW311-SR |

CW350-SR |

|---|---|---|---|

| WATER TYPE | Low or Moderate Hard Water | Hard Water (Scaling) | Extremely Hard Water |

| LSI RANGE | LSI < 2.2 | LSI 2.0 - 2.8 | LSI 2.2 - 3.0 |

| CHEMISTRY | Polyphosphate Orthophosphate PBTC HEDP BZT Dual Polymer System |

PBTC HEDP BZT Dual Polymer System PTSA |

PBTC BZT Dual Polymer System PTSA |

| DOSING | 25 PPM | 25 PPM | 25 PPM |

| PACKAGING | 25 lb box (10 2.5lb bags) | 25 lb box (10 2.5lb bags | 25 lb box (10 2.5lb bags) |

BIOCIDES

We offer oxidizing and non-oxidizing biocides to complete your water treatment solution.

BROMICIDE® 1” TABLETS |

|

|---|---|

|

BromiCide® is a broad-spectrum bromine based oxidizing biocide. BromiCide tablets are designed for effective microbiological control in open recirculating cooling water systems and industrial process waters. BromiCide tablets are used with the Smart Release® brominator (ox-biocide feeder with biocide membrane basket or BMB). The 1” tablets contain Bromo-chloro-5,5-dimethylhydantoin packaged in a convenient 25lb pail. The dissolution rate of the tablets are dependent on temperature and flow through the system.

|

NON-OXIDIZING BIOCIDE SMART RELEASE® BIO-CLEAR |

|

|---|---|

|

The product is a broad spectrum, non-oxidizing biocide effective against a range of bacteria. The product contains a solid form of 2,2-Dibromo-3- nitrilopropionamide packaged in a Smart Release® membrane canister. The product is designed for use in open recirculating cooling water systems where a 30-day Smart Release® biocide treatment is desired.

|

|

Packaging: 12lb Box |

|

Do you know what you’re looking for?

Continue to Step 3: Select Your Equipment >

SMART FEEDERS

Smart Release Feeders are used to feed both scale and corrosion inhibitors and biocides.

| SPECIFICATIONS | SMALL | MEDIUM | LARGE |

|---|---|---|---|

| Tablet Capacity | 5lbs | 10lbs | 15lbs |

| Membrane Biocide Capacity | 1lb canister: 3lbs 2lbs canister: 4lbs |

1lb canister: 6lbs 2lbs canister: 8lbs |

1lb canister: 9lbs 2lbs canister: 12lbs |

| PVA Biocide Capacity | 4 bags | 6-7 bags | 8-9 bags |

| Feeder Height | 21" | 31" | 49" |

| Basket Height | 19" | 31" | 46" |

| Feeder Width | 11" (including valve) | ||

| Feeder Construction | PVC | ||

| Basket Material | HDPE & UHMWPE | ||

| Max Pressure | 80 PSI @ 130 F | ||

| Recommended Flow | 1-3 GPM | ||

Feeders can be purchased individually or as a pre-assembled skid.

SMART CONSTRUCTION

The simple PVC construction not only looks good today but will look good for years to come.

SCALE & CORROSION

TABLET AND NON-OXIDIZING

BIOCIDE FEEDERS

K-BROM G FEEDERS

(OXIDIZER)

*PRV REQUIRED

MOUNTING KITS

Smart Feeders can be mounted to the floor, wall, or the cooling system. Pre-cut Unistrut® is provided in addition to all hardware and clamps for mounting.

|

Pre-cut Kits Available:

|

EXTRA SMALL SYSTEMS

375,000 gallons of blowdown per year

BASIC

|

|

PREMIUM

|

|

SMALL SYSTEMS

600,000 gallons of blowdown per year

BASIC

|

|

PREMIUM

|

|

MEDIUM SYSTEMS

1,000,000 gallons of blowdown per year

BASIC

|

|

PREMIUM

|

|

LARGE SYSTEMS

1,500,000 gallons of blowdown per year

BASIC

|

|

PREMIUM

|

|

Do you know what you’re looking for?

Continue to Step 4: Installation & Monitoring >

ASSEMBLE FEEDERS

Feeders arrive with required components (ball valves, flow meter, etc.) and assemble in no time.

PLUMB FEEDERS TOGETHER

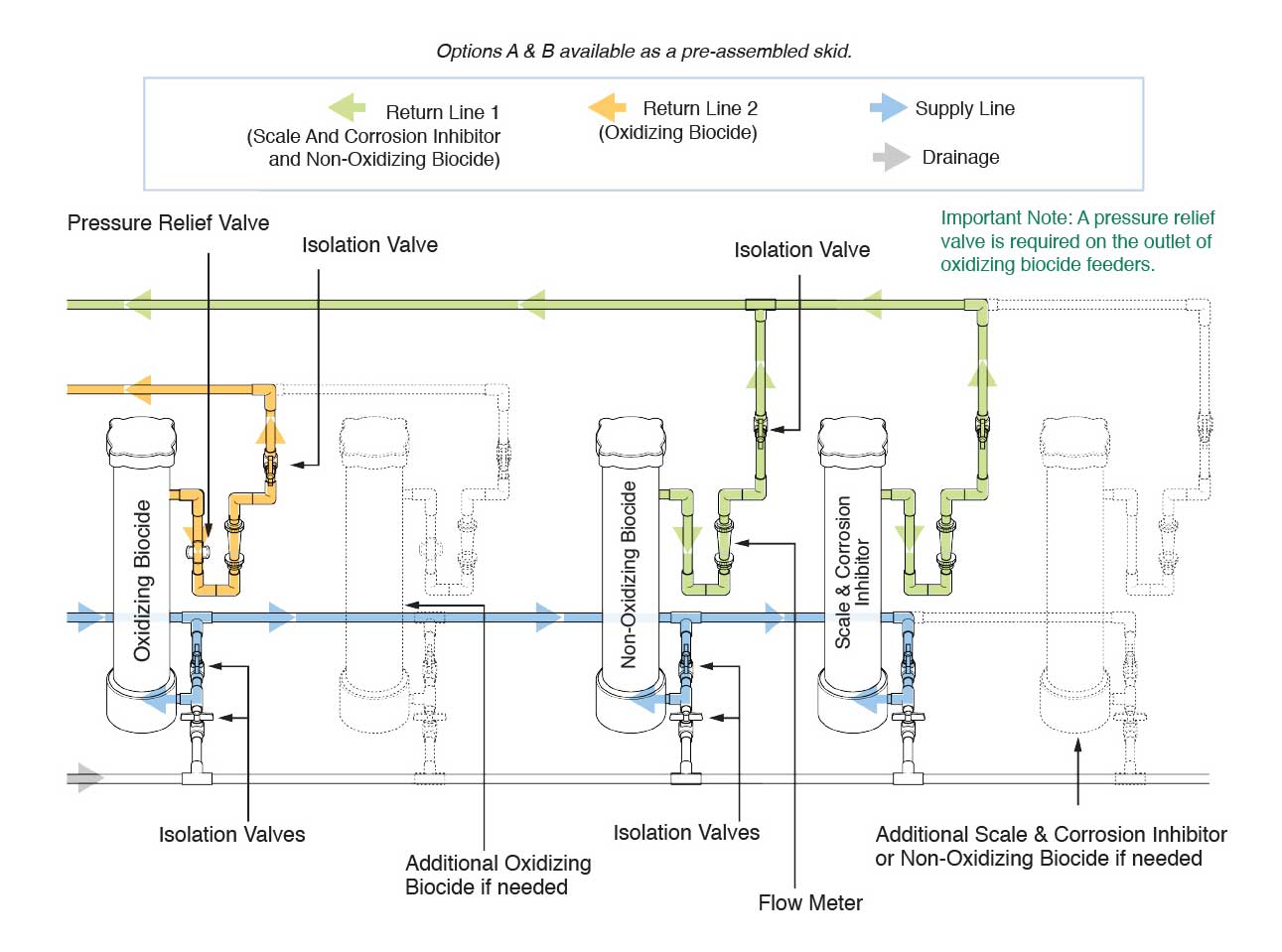

Proper installation is depicted in the diagram below.

SECURELY MOUNT

Securely mount to ground, wall or tower.

PROVIDE WATER SUPPLY & RETURN LINES TO COOLING SYSTEM

Feed system uses recirculating water as supply and requires two return lines to the tower.

Our water treatment specialists are ready to help you select the right components to optimize the performance of your solid feed system and convert from liquid chemistries.